Lithium Production Water Filtration System Retrofit in Sichuan

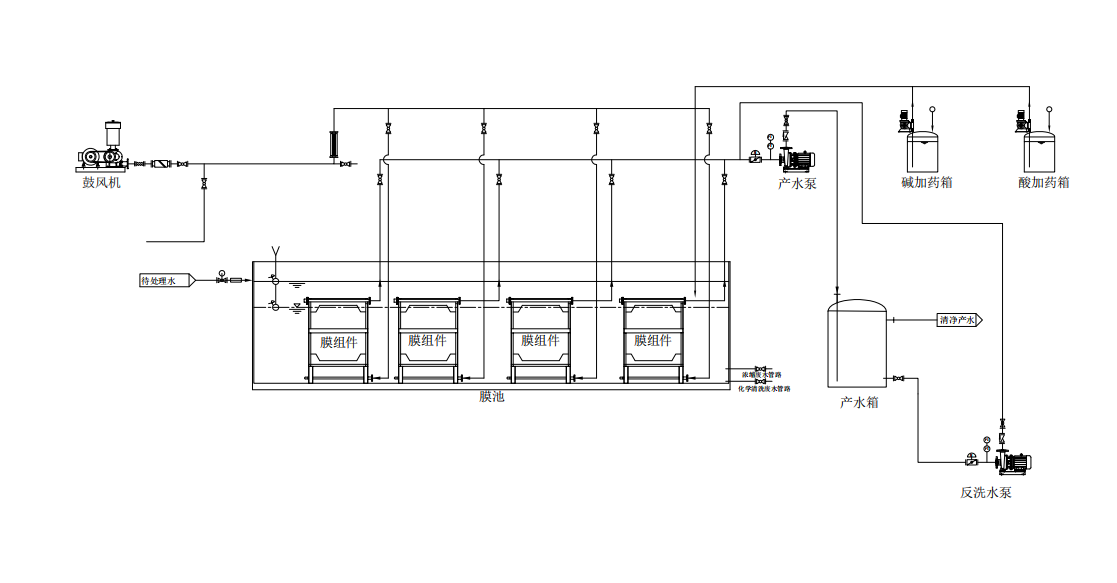

summary:600t/d SUF (Submerged Ultrafiltration)

Capacity: 600 t/d

Process: SUF (Submerged Ultrafiltration)

Effluent Water Quality: Compliant with the enterprise's production water standards

Project Date: July 2020

Highlights:

The lithium production plant requires approximately 600 tons/day of production water. The raw water, sourced from minimally pretreated tap water, contains harmful substances such as chlorine, chloroform, heavy metals, organic pollutants, E. coli, sediment, and rust. These contaminants severely impact the cleaning cycles and efficiency of downstream ultrafiltration (UF) and reverse osmosis (RO) systems, accelerating RO membrane fouling and shortening membrane lifespan.

Original System Issues:

-

A 400 m² ceramic membrane pretreatment system (designed for 600 m³/day) from a domestic supplier operated at only 50% of its design capacity due to severe membrane fouling.

-

Frequent pipe ruptures at water supply points and inconsistent water quality rendered the system unable to meet UF feed requirements.

Retrofit Solution:

The plant upgraded to Weclean Ceramic Flat Membrane Filtration System, implementing the following improvements:

1. Replaced 4 membrane modules to restore filtration efficiency.

2. Added aeration blowers for air scouring to mitigate membrane fouling.

3. Introduced biocides and algaecides to control microbial contamination.

Post-Retrofit Performance:

1. Stable Production Capacity: Stabilized at 30 m³/h.

2. Initial Operating Pressure Differential: Stabilized at 11 kPa.

3. Cleaning Frequency: Reduced to once every two months.

4. Effluent Turbidity: Consistently below 0.5 NTU, ensuring compliance with UF/RO feed specifications.

Popular Applications