Ceramic Flat Membranes: A Green Filtration Solution Under Europe’s New Environmental Regulations

summary:EU Fluorine Ban: How Ceramic Flat Membranes Emerge as Green Water Filtration Solutions Amid PVDF Phase-Out?

Global Fluorochemical Crackdown: A Chemical Revolution Reshaping Industry Standards

The European Chemicals Agency (ECHA) recently revealed that PVDF membranes – which dominate 70% of the global ultrafiltration/microfiltration market (Global Water Intelligence) – face potential EU-wide restrictions due to their PFAS content. This aligns with France’s 2026 PFAS ban across multiple products and the U.S. EPA’s extended compliance timeline for PFOA/PFOS concentration limits.

As regulatory storms intensify, ceramic membranes emerge as the game-changer. With growth in installations, they are redefining water treatment’s core logic – offering a PFAS-free, durable alternative while PVDF-based technologies confront unprecedented policy headwinds.

PFAS Under Fire: What’s Driving Global Attention?

PFAS (Per- and polyfluoroalkyl substances) are a group of synthetic organic compounds characterized by carbon-fluorine bonds, engineered to provide oil-proof, water-resistant, and stain-repellent properties alongside chemical/thermal stability. These "superhero materials" dominate applications from food packaging to water treatment membranes.

"Forever Chemicals" with Eternal Consequences

Their unbreakable C-F bonds make PFAS nearly indestructible in nature. An EPA study on PFOS photolysis revealed an indirect half-life exceeding 3.7 years at 25°C – meaning it takes over 1,350 days for just 50% degradation under ideal conditions.

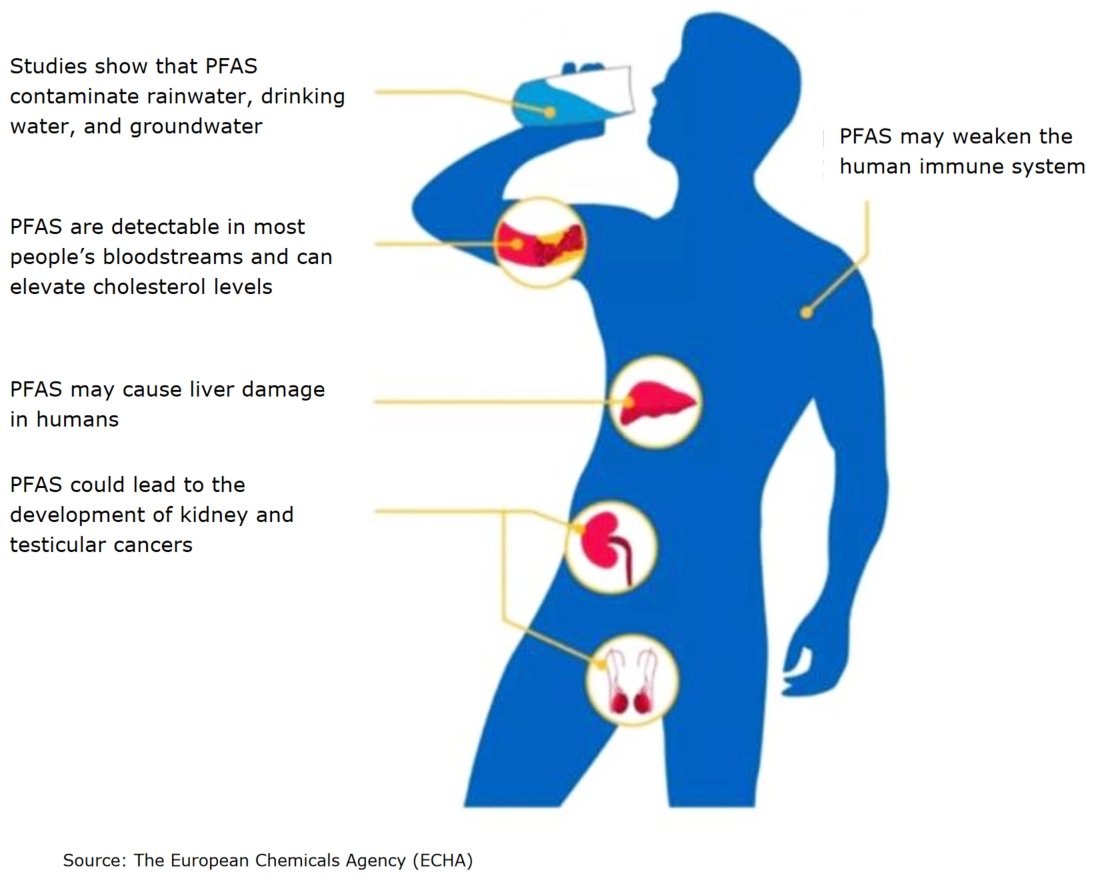

Silent Invasion Through Drinking Water

Research confirms drinking water as the primary PFAS exposure route. Once ingested, these chemicals persist in the human body for 5-8.5 years, accumulating to trigger obesity, endocrine disruption, immune suppression, and cancer. Alarmingly, contaminated water contributes to 6% of deaths in some developing nations – a preventable crisis demanding urgent innovation.

As global regulators escalate restrictions on PFAS—chemicals linked to severe environmental and health risks—companies face a critical dilemma: Can sustainability and high performance coexist under the new rules?

Fluorochemical Bans: The Material Innovation Reshaping Industries

Europe’s Regulatory Hourglass Accelerates:

- Q2 2026: ECHA’s RAC Committee completes sector-specific PFAS risk assessments across 15 industries

- Late 2027: EU member states vote on final PFAS prohibition list

- 2029: Countdown begins for full phase-out of PFAS-containing materials

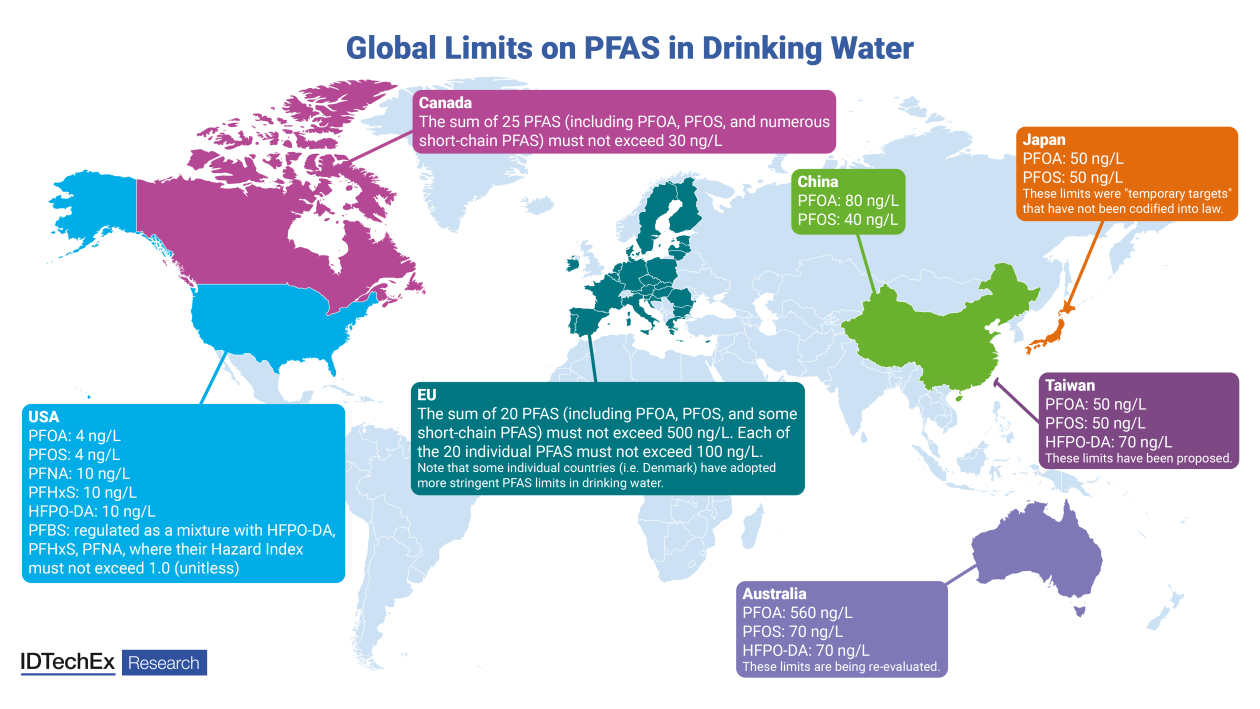

Global Domino Effect in Water Safety:

For manufacturers, non-compliance now risks market access—prompting a strategic shift toward PFAS-free alternatives.

Ceramic Membranes, the PFAS-free solution outperforming traditional technologies, offering unmatched advantages: unrivaled durability, sustainable performance, PFAS-free design. This technology is potential substitute of organic membranes.

The Green Gene of Ceramic Flat Membrane

HIGHLIGHT 1: PFAS-free, Inherent Compliance

- Ceramic Membranes: Composed of high-purity alumina, inherently PFAS-free by design.

- Organic Membranes: 70% of current membrane products rely on PFAS-containing PVDF (polyvinylidene fluoride), facing escalating regulatory bans.

HIGHLIGHT 2: Eco-Performance Revolution

- Decade-Long Durability: Proven operational lifespan exceeding 10 years

- Energy Efficiency: Low-power operation aligned with carbon neutrality goals

- Circular Economy: End-of-life ceramic membranes can be crushed/recycled, achieving 74% lower carbon footprint versus traditional materials (ISO 14044 certified)

HIGHLIGHT 3: Engineering Superiority

- Chemical Immunity: Stable performance in pH 0-14 environments

- Flux Dominance: 3-5x higher flow rates than organic membranes

- Extreme Pressure Tolerance: Withstands >50MPa

Ceramic Solutions: Cracking the Code on 'Forever Pollution’

Industry-Proven Success:

1. Multiple British Waterworks: mandate using ceramic membranes, with the world’s largest ceramic membrane-based drinking water plant set to launch near Birmingham next year.

2. India Waterworks: Reduced footprint by 67% versus traditional sand filtration systems while achieving 99.99% pathogen removal – delivering WHO-Grade A water directly to taps.

3. Middle East Waterworks: Ceramic membranes enhance filtered water quality while reducing reverse osmosis costs.

4. Singapore Waterworks: Replaced 50% of organic membranes with ceramics.

Ceramic technology is poised to revolutionize the water industry! Delivering far greater benefits than today’s prevalent organic membranes, ceramic solutions offer unparalleled advantages. Accelerating the transition to ceramic flat membranes serves the strategic interests of all stakeholders—from suppliers to end-users.

#PFAS Bans #Sustainable Industry #Innovation Leadership

Popular Applications